ProGuard® the right chemical filter media to remove corrosive and odorous chemical gases.

Chemical Filtration Media

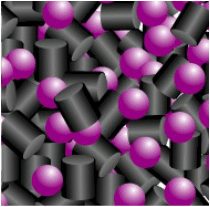

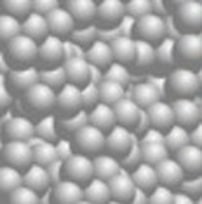

ProMark’s spherical, porous pellets or granules remove gaseous pollutants from air using a chemical process known as chemisorption. The gas-phase media breaks down harmful airborne gases into harmless materials that are trapped inside the pellet. This process is instantaneous and irreversible. ProGuard® Media are packaged in one cubic foot boxes, 50 or 55 lb. bags, Bulk bags up to 2,000 lbs, and drums.

ProMark Chemical Filtration Media

Potassium permanganate on alumina Sodium permanganate on alumina Blends Impregnated alumina Plain activated carbons Impregnated carbon Catalytic carbon Desiccant

Contact us for help selecting the right media

Potassium permanganate on alumina

ProGuard® 100 is robust alumina spherical media with potassium permanganate suitable for machine filling of sachets. These sachets with PG 100 can be placed in moist places like refrigerators to remove ethylene from ripening fruits to retired the ripening process. The sachets prevent spoilage of fruits and vegetables onboard ships, long term produce storage, and home refrigerators. ProGuard® 200 is spherical alumina with permanganate that removes toxic, corrosive, and odorous gases. It benefits HVAC systems at refineries, steel mills, wastewater treatment plants, hospitals, museums, commercial buildings, labs, and elsewhere by converting the odorous gases to safe byproducts in the spheres. ProGuard® 200 adsorption and chemical reaction processes remove such contaminants as hydrogen sulfide, sulfur dioxide, nitric oxide, and formaldehyde. This media has structured pores that chemisorb, adsorb, and accommodate chemical by-products of the chemical reaction. Another benefit: this media contains little dust low. ProGuard® 300 features proprietary chemistry, along with potassium permanganate, that enables it to remove greater quantities of acid gas. It adsorbs and chemisorbs corrosive gases with twice the chemistries as ProGuard® 200. This is important for export purchases since the freight is the same as ProGuard® 2000 but it lasts longer.

ProGuard 200 Datasheet – ProGuard 300 Datasheet – ProGuard 400 Datasheet

Sodium permanganate on alumina

ProGuard® 500 uses 12 percent sodium permanganate on alumina and proprietary chemistries to raise chemisorbant performance. We formulated it to achieve the highest oxidation capacity to do more in the same space than other alumina media.

Blends

ProGuard 200 Datasheet – ProGuard 300 Datasheet – ProGuard 400 Datasheet – ProGuard 600 Datasheet – ProGuard 900 Datasheet

Impregnated alumina

Plain activated carbons

ProGuard® 600 is made of virgin, coconut-shell-based, granular carbon, which removes from the air a broad range of gaseous compounds. It is routinely used in HVAC systems in offices, machine shops, lounges, and restaurants as well as in commercial and industrial buildings. The ProGuard® 600 adsorption process removes such common contaminants as cigarette smoke, VOCs, acetic acid, chlorine, methyl alcohol, ozone, and toluene. ProGuard® 700 is a coal‑based carbon that removes a broad range of gaseous compounds from the air. It is routinely used in HVAC systems in offices, machine shops, bars, restaurants and industrial buildings. Common contaminants removed by the ProGuard® 700 adsorption process are: acetic acid, alcohols, and VOCs (benzene, chlorine, garlic, onion, gasoline, ozone, phenol and tobacco smoke).

Impregnated Carbon

ProGuard® 800 is an acid impregnated carbon and removes base pH gases (8-14 pH) from the air. It removes corrosive gases and is routinely used in HVAC systems in chemical plants, blue print shops, animal labs and zoos. Common contaminants removed by the ProGuard® 800 absorption and chemical reaction process are ammonia (NH3) and low molecular weight amines. ProGuard® 900 is an alkali-impregnated carbon that removes from the air acidic gases (1-7 pH). It is typically used in HVAC systems in refineries, paper mills, wastewater plants, steel mills, and industrial buildings. It protects computers and people and removes odors. ProGuard® 900‘s chemisorption process are: hydrogen sulfide, sulfur dioxide, nitric oxides, mercaptans, chlorine. ProGuard® 945 is a spherical ball of activated carbon powder and alumina with other binders impregnated with alkali chemistries to enhance removal of acids, chlorine, H2S, SO2, NOx. Where there are corrosive environments, ProGuard® 945 will protect sensitive electronics, electrical equipment, and people from hazardous gases.

ProGuard 800 Datasheet – ProGuard 900 Datasheet – ProGuard 945 Datasheet

Catalytic Carbon

New as of 7-17

ProGuard® 950 is an activated catalytic carbon specially developed for removing hydrogen sulfide (H2S), and other sewage-like odors. Rated at 0.3 g/cc H2S, it boasts the highest capacity for removing H2S of any gas-phase media. It is made from coconut shell carbon, a renewable resource, and comes in 4-millimeter pellets. Our special manufacturing process eliminates the post-activation impregnation typically used. ProGuard 950’s high capacity and low density means that fewer pounds are required per unit of volume—making it the lowest cost media per pound of H2S removed.