UV light combined with a special photocatalyst delivers sustainable results - extending the life of the media by years.

What came before success

In 2003 we started researching how to make what we sell more sustainable. Gas-phase media is like a razor blade that services its purpose but must be replace relatively often. Media becomes spent in a matter months to a year so the replacement costs can be significant if the gas pollutants are in 5 parts per million or more constantly.

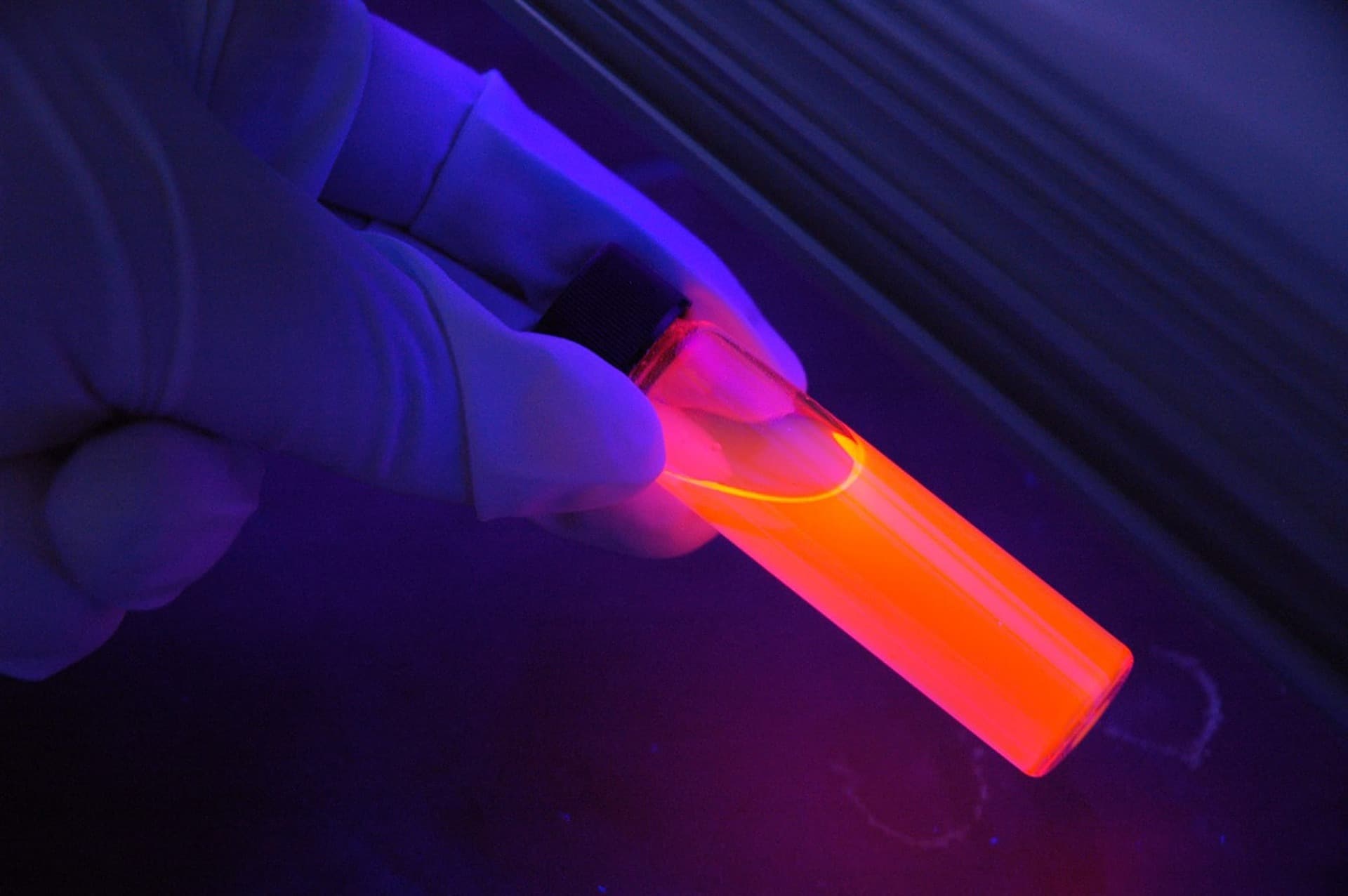

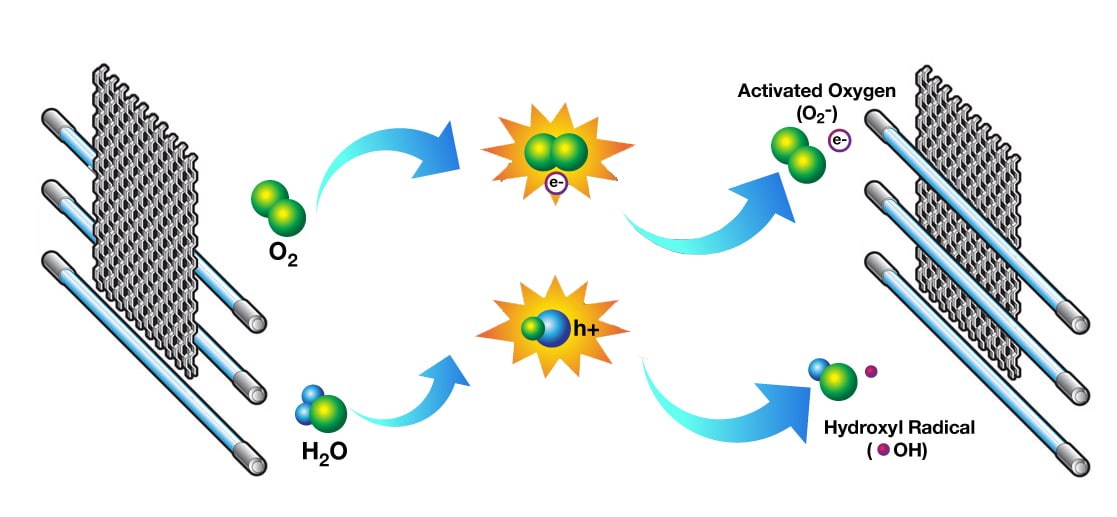

We learned about the power of combining ultraviolet light with a special photocatalyst. Testing and everyday experience taught us how we could safely maximize the results of this process technology. Controlled Dynamic Chemistry™ generation delivers safe, sustainable air purification at the highest level.

How does Dynamic Chemistry™ generation work?

Ultraviolet lamps work with a photocatalyst applied to a special substrate. The substrate allows air to flow through it with very little resistance but forces all of the air to come in contact with the catalyst-coated surfaces.

As polluted air flows through the special catalyst and ultraviolet lamp stages, Dynamic Chemistry™ generation destroys VOCs by breaking up hydrocarbon molecules into CO2 and H2O. We hold four patents associated with this process.

Our first full-scale, commercial test proved a remarkable success. Three Total Spectrum® air purification systems were placed in a smoking casino’s new slots gaming area. After the casino had been operational for 60 days, independent technicians measured air in the casino for all organic gases and compounds in multiple locations.

The results exceeded expectations: Total VOC levels fell at or below what the lab could measure using a gas chromatograph. VOCs measured in 200-300 parts per trillion as compared to outside air that has VOCs measured in parts per million. Therefore the casino could reuse the Total Spectrum® air purification sytem’s purified air and thus save on HVAC operating costs.