Minimize the frequency and severity of chemical plant accidents.

Toxic Gas Scrubbing

The EPA Risk Management Program for Chemical Accident Release Prevention “requires regulated facilities to develop and implement appropriate risk management programs to minimize the frequency and severity of chemical plant accidents.” ProMark can help you comply with the requirements and build the right scrubber for your needs.

Contact Us for More Information or a Quote

Common Problems

Toxic Gas

Problem: Accidental releases of toxic gases stored for process use.

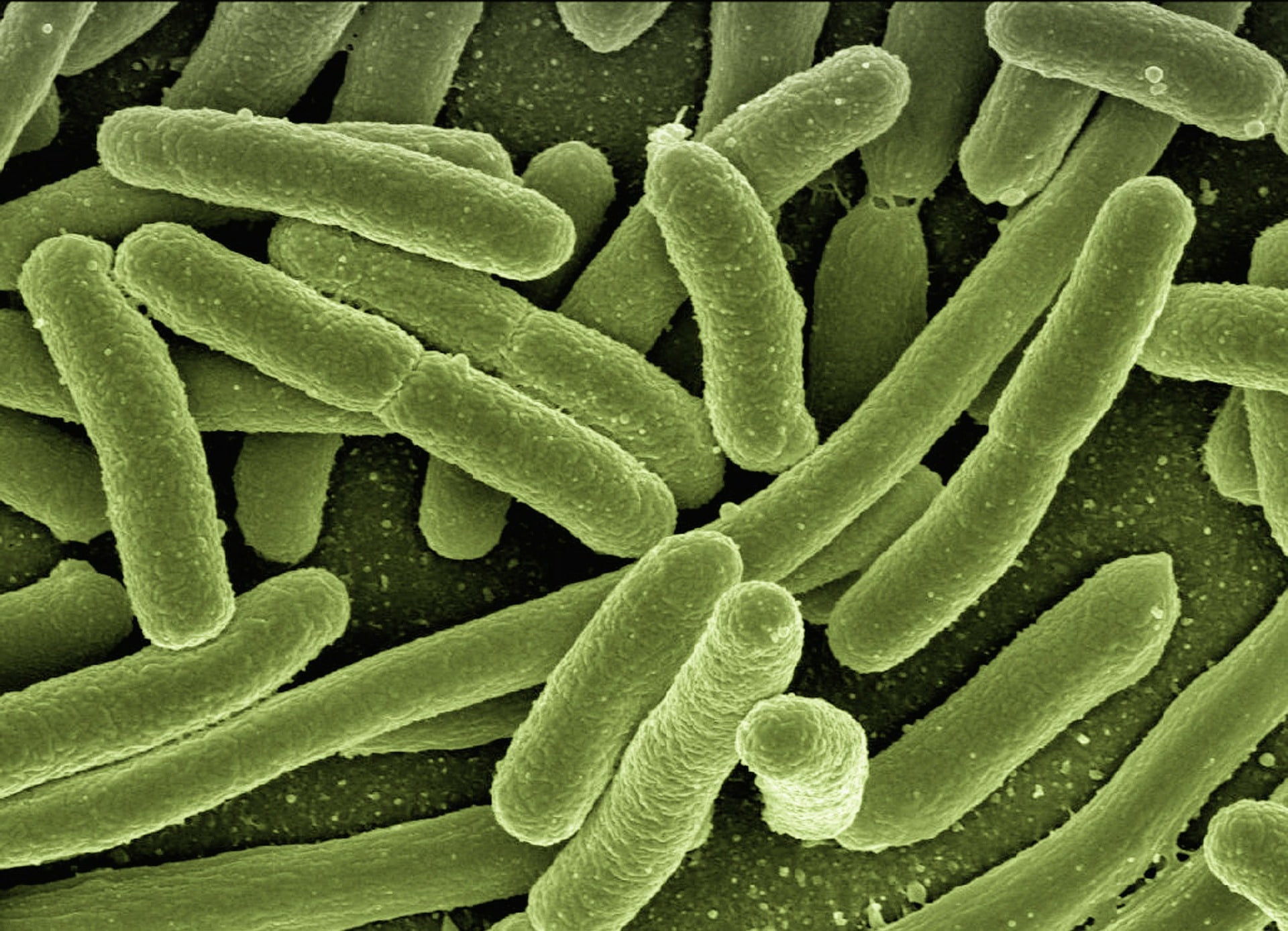

The operators of water and wastewater treatment facilities, oil and gas refineries, and pulp and paper mills are concerned about accidental releases of toxic gases stored for use in various processes. A toxic gas release poses a very real threat to human life in the surrounding community, up to a five-mile radius. Built to mitigate risk to human life in potentially catastrophic gas releases, scrubbers are designed to handle releases from 150 pounds to more than 3 tons of gas.

Solution: A bulk-fill scrubber with ProGuard® 400

Chlorine is a common disinfectant used to prevent pathogens from developing in purified drinking water during its travel from the water treatment plant to your faucet. Water facilities typically use 2,000-pound cylinders of chlorine under pressure to be injected into the final stage of the water plant process. Even with modern methods, there is a slight possibility an accident could cause the discharge of chlorine gas into the building and air. To prevent poisoning employees, neighbors, pets, killing trees and in general creating a toxic release, technicians install emergency gas scrubbers. Specially designed to quickly handle a large volume of chlorine gas, these scrubbers absorb the heat generated and have a fan that can withstand the chlorine. ProMark’s ProGuard® 400 media neutralizes chlorine, making the air safe and protecting the environment and nearby people from the toxic gas. Pease call or write for more information.