Multiple air exchanges per hour and five stages of advanced air purification

ProMark Associates is known for engineering highly effective clean-air solutions for large commercial businesses and buildings worldwide. Their newest clean-air product is the ProGuard® Mobile Air Purifier. Not to be confused with small portable air filters that are better suited to filtering residential-size rooms, this industrial-grade system can remove particles, VOCs, and pathogens. It can deliver six air changes per hour (recommended by the ASHRAE trade group) in a room of up to 1,500 square feet. The Mobile Air Purifier is powerful, quiet and can be easily rolled into place on its casters.

A different approach to making air safe

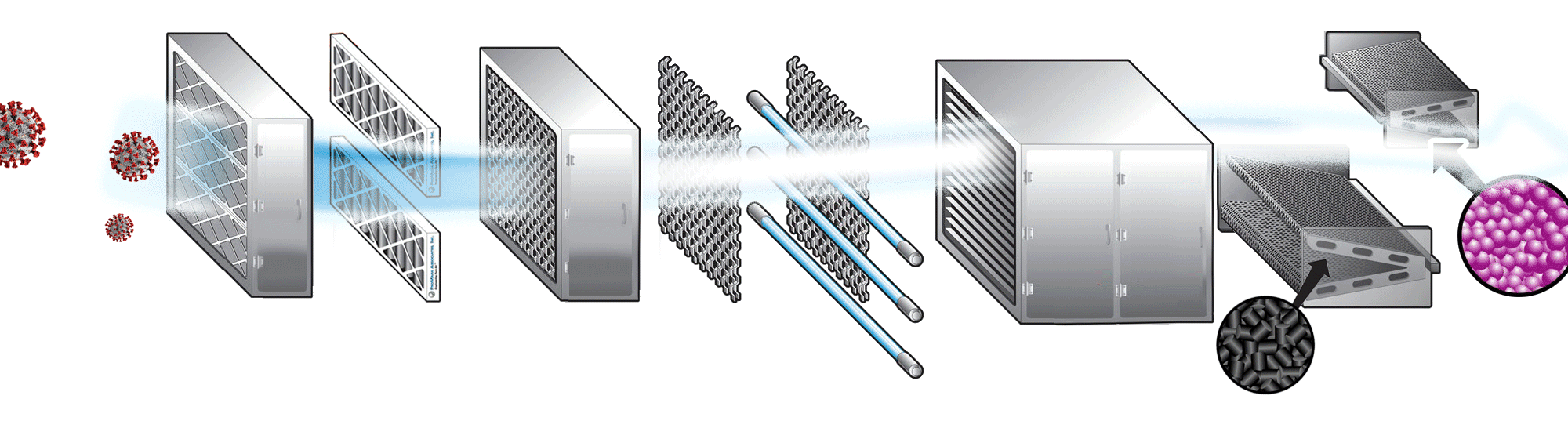

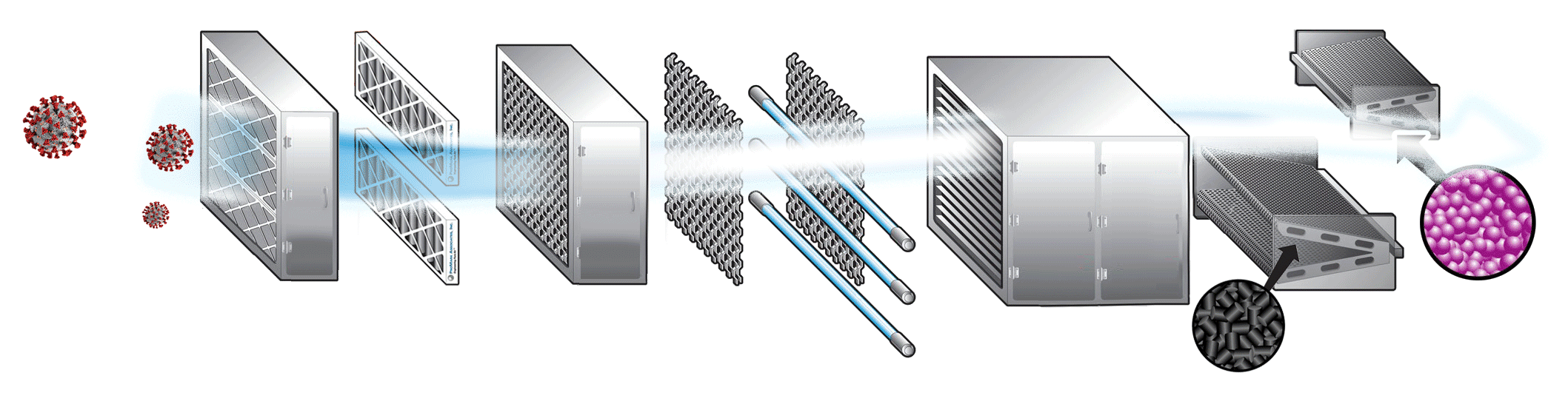

The ProGuard® Mobile Air Purifier uses a centrifugal fan to circulate air through five stages of protection for an unprecedented attack on airborne viruses, bacteria, mold, and even foul odors. This capability, combined with its 1,200-cfm fan capability, is a key difference with other portable air-filtration systems. Instead of relying exclusively on mechanical air filtration, UV-C light and chemical-media filters are used to kill pathogens and remove odors.

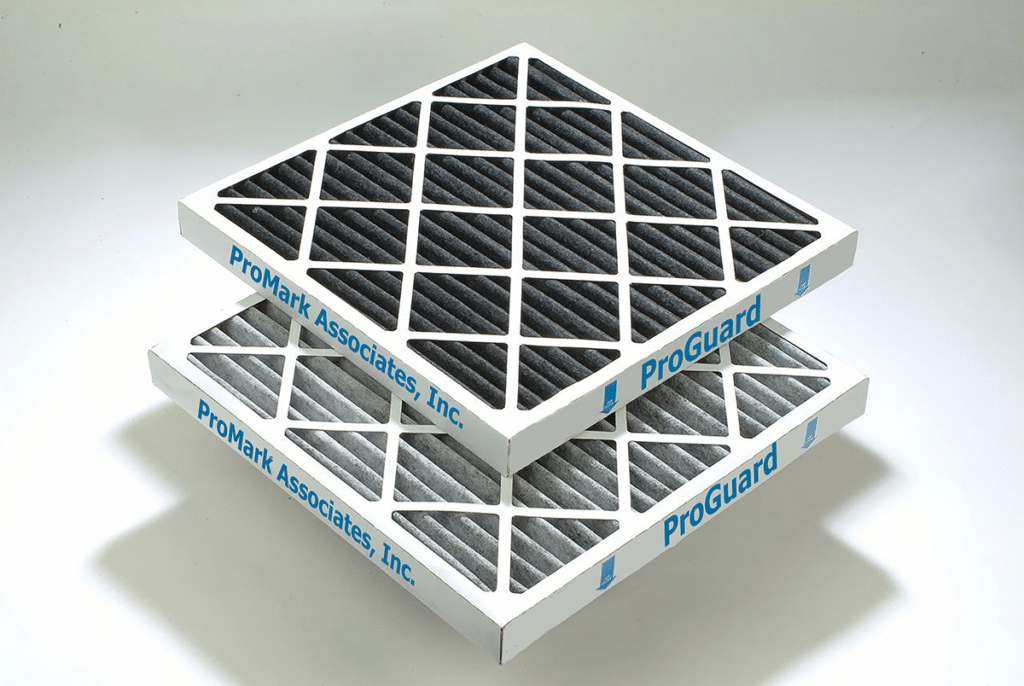

Stage 1 filters incoming air through a 24 x 24 x 2-inch MERV 8 filter, with an antimicrobial coating to enhance contaminant removal.

Stage 2 is a germicidal UV-C light chamber that helps to prevent transmission of viruses and microorganisms and kills pathogens that might otherwise accumulate on filter media. A recent study by Columbia University found that UV-C light can kill 99.9% of the novel coronavirus.

Stage 3 is a 24 x 24 x 4-inch MERV 11 filter with high dust-holding capacity for long life with a low-pressure drop. Combined with the Stage 1 MERV 8, this provides MERV 13 filtration capacity without the high cost of MERV 13 filters. This level of filtration is recommended by ASHRAE to address aerosols carrying COVID-19 and other viruses.

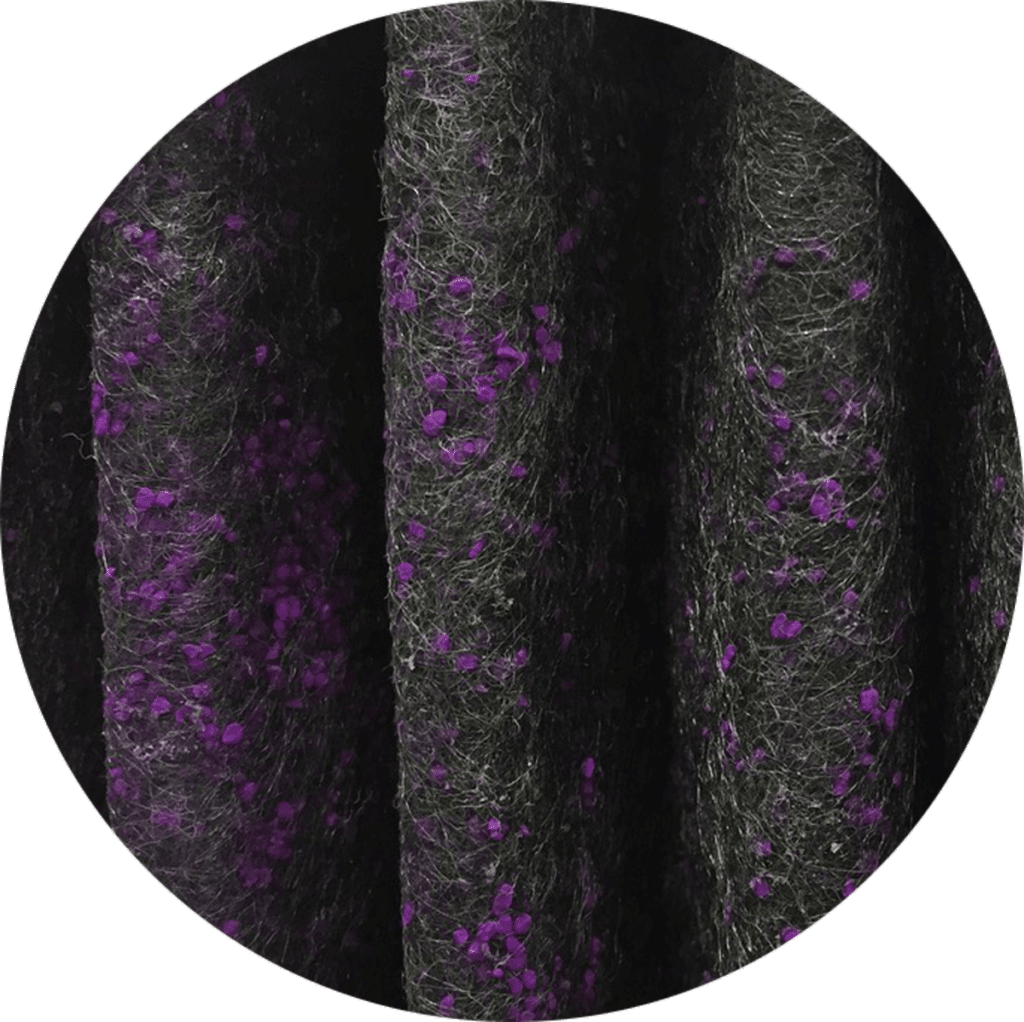

Stage 4 is another attack on pathogens with a 4-inch-thick gas-phase filter made of 100% activated carbon which removes gaseous pollutants untouched by particulate filters.

Stage 5 is a 24 x 24 x 2-inch MERV 8 final filter with ProGuard® 300 potassium permanganate granules to disinfectant air flow and ensure the removal of any remaining gases and pathogens.

The New ProGuard Mobile Air Purifier

Jeff Roseberry, president of ProMark Associates, said, “Until now, the only way to provide such a high level of air filtration has been by means of a custom-designed and built system to be incorporated into a central HVAC unit.” Roseberry added, “While those systems are the gold standard for commercial building air filtration, they require a long lead time to build and match the HVAC system installation. Our Mobile Air Purifier can provide similar airborne pathogen protection with no installation.”

The ProGuard® Mobile Air Purifier is designed for use in almost any commercial space, including schools & universities, healthcare, dentists’ offices, restaurants, commercial offices, senior living, retail, manufacturing, fitness centers and is plug and play. The standard-size filters and UV-C lamps are user replaceable. Required power is 115-127VAC at 330 watts (2.9A). At full capacity, the noise level is a whisper-quiet 22dB. It is constructed of double-wall steel with sound-deadening insulation and easy-roll industrial-grade casters for ease of moving to any location.

It’s no secret that 2020 has upended the traditional workplace while permanently changing worker’s expectations in regard to office safety and air quality of the office environment. With vaccine distribution fueling progress in the right direction, more and more offices are slowly bringing workers back into offices, while trying to mitigate Covid-19 risks through social distancing and mask-wearing guidelines. However, in the minds of workers – is that enough? According to a new poll from

It’s no secret that 2020 has upended the traditional workplace while permanently changing worker’s expectations in regard to office safety and air quality of the office environment. With vaccine distribution fueling progress in the right direction, more and more offices are slowly bringing workers back into offices, while trying to mitigate Covid-19 risks through social distancing and mask-wearing guidelines. However, in the minds of workers – is that enough? According to a new poll from

To better understand how a virus can be removed from the air, let us first review what a virus is. Viruses are made up of a piece of genetic code, such as DNA or RNA, and are protected by a coating of protein. Once an individual becomes infected, viruses invade host cells within the body and replicate, producing more viruses. COVID-19 is a new variant of a novel coronavirus. But even though it is new, it is still an organic pathogen made up of carbon, oxygen, and hydrogen like all other viruses.

To better understand how a virus can be removed from the air, let us first review what a virus is. Viruses are made up of a piece of genetic code, such as DNA or RNA, and are protected by a coating of protein. Once an individual becomes infected, viruses invade host cells within the body and replicate, producing more viruses. COVID-19 is a new variant of a novel coronavirus. But even though it is new, it is still an organic pathogen made up of carbon, oxygen, and hydrogen like all other viruses. During this phase, air flows through the prefilters to remove particulates from the air. This filter is just the beginning of the process that removes larger debris and materials from the air prior to chemical filtration.

During this phase, air flows through the prefilters to remove particulates from the air. This filter is just the beginning of the process that removes larger debris and materials from the air prior to chemical filtration. Next, contaminated air passes through two catalyst screens that are energized by ultraviolet light lamp energy. The catalyst forms reactive chemistries on its’ surface due to the UV energy that multiplies the intensity of the UV multiple times. As the air comes in contact with a catalyst-coated surface, the organics are broken down to their base components of CO2 and water as moisture. We call this Dynamic Chemistry® because it is constantly generating these chemistries that destroys pathogens and VOCs instantaneously!

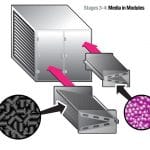

Next, contaminated air passes through two catalyst screens that are energized by ultraviolet light lamp energy. The catalyst forms reactive chemistries on its’ surface due to the UV energy that multiplies the intensity of the UV multiple times. As the air comes in contact with a catalyst-coated surface, the organics are broken down to their base components of CO2 and water as moisture. We call this Dynamic Chemistry® because it is constantly generating these chemistries that destroys pathogens and VOCs instantaneously! During the final stage, any remaining air pollutants are removed through gas-phase filtration. The Total Spectrum utilized unique, patented modules. The innovative design doubles the media capacity which increases surface contact and minimizes air resistance.

During the final stage, any remaining air pollutants are removed through gas-phase filtration. The Total Spectrum utilized unique, patented modules. The innovative design doubles the media capacity which increases surface contact and minimizes air resistance.